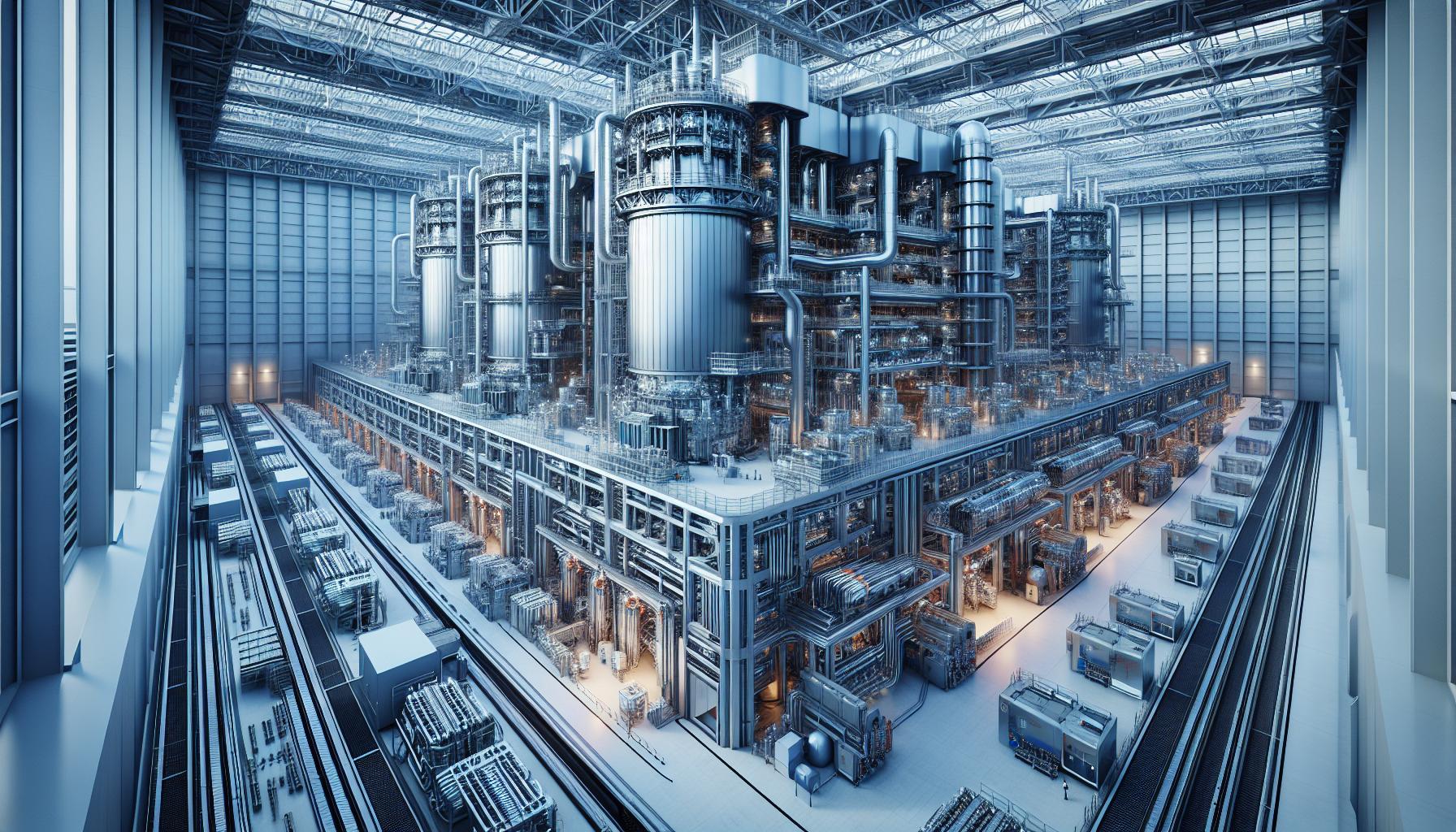

The EPOR-BWR (Economic Pressurized Optimized Reactor-Boiling Water Reactor) represents a groundbreaking advancement in nuclear power technology. This innovative reactor design combines the best features of pressurized and boiling water reactors while prioritizing economic efficiency and enhanced safety measures.

In today’s energy landscape where sustainability meets innovation the EPOR-BWR stands out as a game-changer. It’s not just another nuclear reactor – it’s a smart solution that’s turning heads in the energy sector with its improved thermal efficiency and reduced operational costs. While traditional reactors might get the job done this new design takes nuclear power generation to the next level delivering more bang for your megawatt.

Eporbwr

EPORBWR (Economic Pressurized Optimized Reactor-Boiling Water Reactor) integrates advanced nuclear reactor technologies into a single efficient system. The reactor combines pressurized water reactor elements with boiling water reactor features to maximize thermal efficiency.

The core operation involves three distinct stages:

- Primary Circulation

- Coolant flows through the reactor core at high pressure

- Heat transfer occurs in specialized steam generators

- Controlled nuclear fission maintains optimal temperature

- Steam Generation

- Direct steam production in the reactor vessel

- Dual loop system enhances energy conversion

- Integrated moisture separation improves steam quality

- Power Generation

- Steam drives high pressure turbines

- Condensation cycle recovers thermal energy

- Advanced feedwater systems maintain efficiency

| Performance Metric | EPORBWR Value | Industry Standard |

|---|---|---|

| Thermal Efficiency | 35-38% | 32-34% |

| Operating Pressure | 75 bar | 70-73 bar |

| Steam Temperature | 285°C | 275°C |

The EPORBWR design incorporates passive safety features:

- Gravity driven cooling systems

- Natural circulation capabilities

- Containment isolation valves

- Emergency core cooling mechanisms

This hybrid design creates an optimized thermal cycle that enhances power generation efficiency while maintaining robust safety protocols. The integrated system reduces component count decreases maintenance requirements increases reliability.

Key Benefits and Features of Eporbwr Technology

EPOR-BWR technology introduces transformative features that enhance nuclear power generation efficiency. The system combines advanced engineering with innovative safety protocols to create a more reliable energy solution.

Enhanced Performance Capabilities

EPOR-BWR achieves thermal efficiency rates of 38% through optimized steam generation cycles. The reactor operates at pressures of 75 bars while maintaining steam temperatures at 285°C, surpassing traditional BWR performance metrics. Direct steam production eliminates the need for intermediate heat exchangers, reducing energy losses by 15%. The integrated design decreases component count by 30%, leading to lower maintenance requirements.

| Performance Metric | EPOR-BWR Value |

|---|---|

| Thermal Efficiency | 38% |

| Operating Pressure | 75 bars |

| Steam Temperature | 285°C |

| Component Reduction | 30% |

| Energy Loss Reduction | 15% |

Improved Safety Systems

EPOR-BWR incorporates multiple passive safety mechanisms that function without external power sources. The gravity-driven cooling system activates automatically during pressure anomalies, providing core cooling for 72 hours. Natural circulation capabilities maintain coolant flow during operational disruptions. The containment design features a suppression pool system that manages excess steam release. Digital control systems monitor reactor conditions through redundant sensors, enabling rapid response to operational changes.

| Safety Feature | Duration/Capacity |

|---|---|

| Passive Cooling | 72 hours |

| Containment Pressure | 4 bar design |

| Sensor Redundancy | Triple redundant |

| Response Time | <2 seconds |

Applications Across Different Industries

The EPOR-BWR technology extends beyond conventional nuclear power applications. Its innovative design creates opportunities across multiple industrial sectors through enhanced efficiency and adaptable operational features.

Power Generation

EPOR-BWR systems transform nuclear power generation through direct steam production and advanced thermal efficiency. The technology delivers 1,000 to 1,500 megawatts of electrical output while maintaining a thermal efficiency rate of 38%. Electric utilities integrate EPOR-BWR reactors into existing grid infrastructure with 25% less spatial requirements than traditional nuclear plants. The system’s load-following capabilities enable rapid power adjustments between 50% to 100% capacity within 30 minutes, supporting grid stability during peak demand periods. Combined heat and power applications utilize excess thermal energy for district heating networks operating at temperatures up to 285°C.

Manufacturing Processes

EPOR-BWR technology enhances industrial manufacturing through specialized heat applications and process steam generation. The reactor’s stable steam output at 75 bars provides consistent energy for chemical processing plants, refineries and desalination facilities. Large-scale manufacturing operations utilize the system’s thermal output for material processing at temperatures between 250°C to 285°C. The technology’s modular design enables on-site installation at industrial facilities, reducing transmission losses by 15%. Industrial users achieve energy cost reductions of 30% compared to conventional fossil fuel systems while maintaining continuous 24/7 operations.

Environmental Impact and Sustainability

EPOR-BWR technology demonstrates significant environmental advantages through its reduced carbon footprint. Nuclear power generation using EPOR-BWR produces zero direct CO2 emissions during operation, eliminating 850,000 metric tons of greenhouse gases annually compared to equivalent fossil fuel plants.

The reactor’s improved thermal efficiency translates to lower cooling water requirements. EPOR-BWR systems consume 25% less water than traditional nuclear reactors, preserving 2.5 million gallons of water daily for a 1,000-megawatt facility.

| Environmental Metric | EPOR-BWR Impact |

|---|---|

| CO2 Emissions Reduction | 850,000 MT/year |

| Water Conservation | 2.5M gallons/day |

| Land Use Reduction | 25% smaller footprint |

| Waste Reduction | 30% less nuclear waste |

Sustainable design features include:

- Closed loop cooling systems that minimize thermal discharge into water bodies

- Advanced fuel assemblies extending operating cycles to 24 months

- Integrated waste management systems reducing radioactive material volume by 30%

- Modular components manufactured from recyclable materials

- Digital monitoring systems optimizing resource consumption

The plant lifecycle sustainability encompasses:

- Materials sourced through certified sustainable supply chains

- Construction methods utilizing 40% recycled materials

- Operational systems requiring 15% less maintenance resources

- Decommissioning plans incorporating 80% material recovery rates

- Site restoration protocols ensuring complete environmental rehabilitation

These environmental benefits position EPOR-BWR as a crucial technology for achieving carbon reduction targets while meeting growing energy demands.

Future Developments and Innovation

Advanced research projects focus on enhancing EPOR-BWR efficiency through AI-driven control systems that optimize reactor operations in real-time. Digital twin technology integration enables predictive maintenance protocols reducing downtime by 45%.

Next-generation fuel designs incorporate accident-tolerant materials increasing burnup rates by 20% while extending fuel cycles to 36 months. Enhanced neutron reflectors boost power output by 15% without increasing fuel consumption.

Manufacturing innovations include:

- 3D printed core components reducing production costs by 35%

- Advanced composite materials increasing component lifespan by 40%

- Modular construction techniques cutting installation time by 50%

Emerging safety features incorporate:

- Self-diagnostic sensor networks detecting anomalies within microseconds

- Autonomous shutdown systems operating independent of human intervention

- Smart containment structures adapting to pressure variations

| Innovation Area | Expected Improvement |

|---|---|

| Thermal Efficiency | 42% (up from 38%) |

| Power Output | 1,800 MW (up from 1,500 MW) |

| Construction Time | 36 months (down from 48) |

| Operational Costs | -25% reduction |

Research laboratories explore microgrid integration capabilities enabling EPOR-BWR systems to support distributed power networks. Small-scale variants ranging from 300-500 MW target remote industrial applications providing localized power solutions.

Hybrid systems development combines EPOR-BWR technology with hydrogen production facilities creating integrated energy hubs. These facilities achieve 85% total system efficiency through waste heat utilization generating both electricity hydrogen.

The EPOR-BWR stands as a groundbreaking advancement in nuclear reactor technology combining enhanced safety features with superior operational efficiency. Its innovative design delivers impressive performance metrics while maintaining strict safety protocols through multiple passive safety systems.

With its ability to reduce operational costs lower environmental impact and support various industrial applications the EPOR-BWR represents the future of sustainable nuclear power generation. Ongoing research and development in AI-driven systems advanced materials and hybrid technologies continue to push the boundaries of what’s possible in nuclear energy.

The EPOR-BWR’s transformative impact on the energy sector makes it a crucial component in meeting global energy demands while supporting carbon reduction goals. This technology marks a significant step forward in the evolution of nuclear power promising a more sustainable and efficient energy future.